How Foot Pedal Shearing Machines Boost Efficiency & Productivity

- Home

- Shearing Machine

- How Foot Pedal Operation Improves Efficiency in Shearing Machines

- By: Leo Engineers

- Shearing Machine

- 0 Comments

In sheet metal fabrication, every second and every movement matters. Manual shearing machines traditionally require both hands to engage the cutting blade, which can be tiring, imprecise, and time-consuming over long work shifts. That’s where foot pedal operation comes into play—offering hands-free, ergonomic control that can significantly enhance operator productivity and precision.

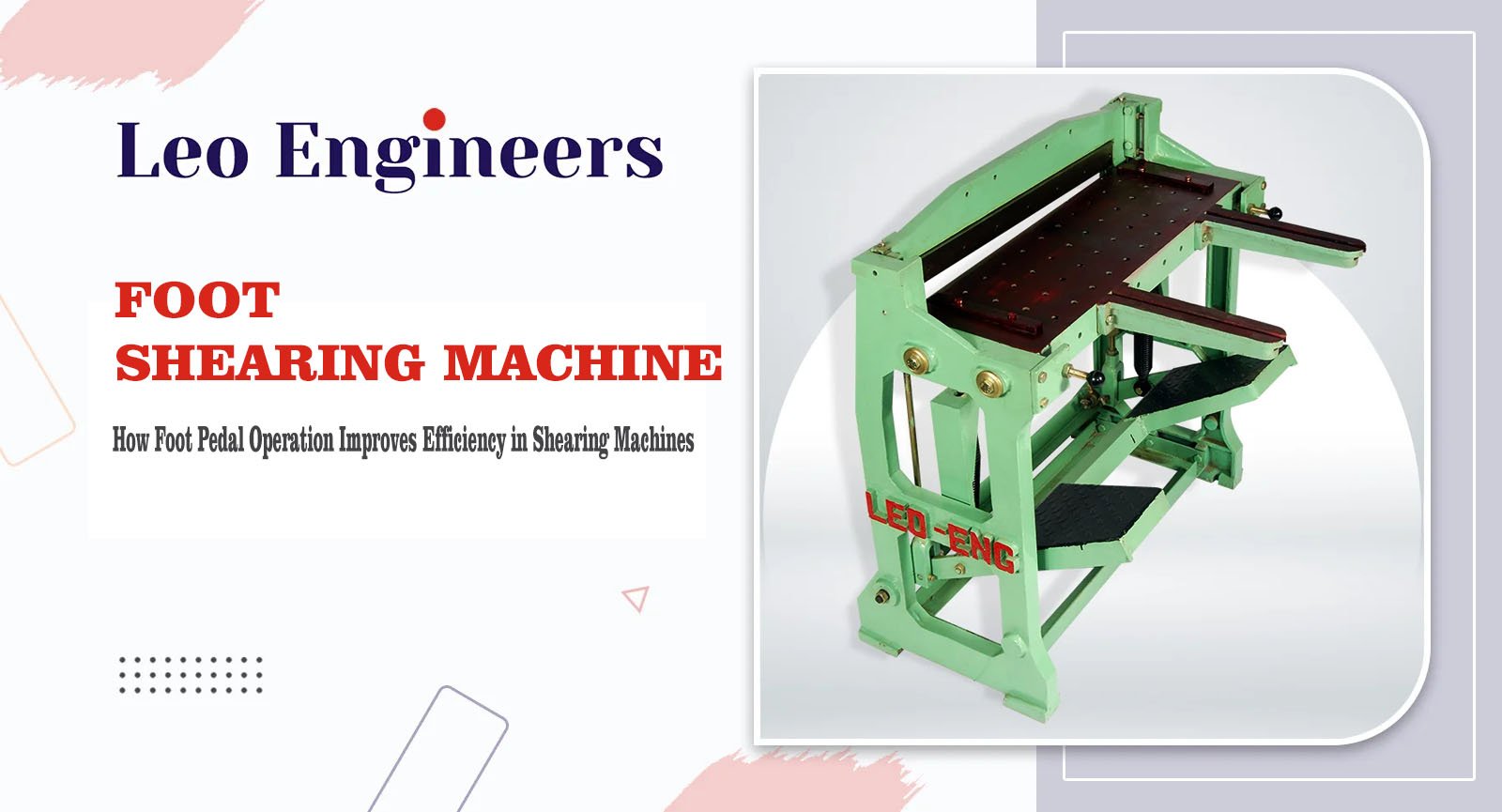

What Is a Foot Pedal Shearing Machine?

A foot pedal shearing machine is a type of mechanical or pneumatic shear operated by pressing a foot pedal. The pedal actuates the cutting blade, allowing the operator to hold and align the sheet metal using both hands while controlling the cut with their foot. This design optimizes workflow and reduces the complexity of operation.

Key Components:

- Foot pedal actuator

- Pneumatic or mechanical cutting blade

- Guide system for alignment

- Safety locks and spring-loaded blade return

Advantages of Foot Pedal Operation

- Hands-Free Control Enhances Precision

By freeing up the hands, operators can position and hold the workpiece more securely. This minimizes slipping or misalignment, resulting in cleaner, straighter cuts—especially on thin or lightweight materials. - Reduced Operator Fatigue

When workers use both hands and body weight to operate conventional levers or cranks, fatigue sets in quickly. Foot pedal operation shifts the load to the leg muscles, allowing the upper body to remain relaxed. This increases stamina and reduces the chance of strain-related injuries. - Faster Production Speed

Foot operation is generally quicker and smoother than manual lever-based control. With rapid foot actuation, the operator can cut more sheets in less time, boosting throughput without compromising accuracy. - Improved Workplace Safety

Modern foot pedal shears come with built-in safety mechanisms such as return springs, emergency stops, and guard rails. Since hands remain clear of the blade during operation, the risk of hand injury is significantly reduced.

Use Case: Shearing in a Small Fabrication Shop

Consider a small HVAC ducting manufacturer that handles light-gauge galvanized sheets. By upgrading to a foot pedal pneumatic shear, they reduced cut-time per sheet by 30%, minimized rework due to miscuts, and reduced operator complaints of fatigue. This change increased daily output and worker satisfaction—without hiring extra hands.

When Is a Foot Pedal Shear Ideal?

- Low to Medium Volume Operations: Efficient for batch jobs without needing full automation.

- Precise, Repetitive Cuts: Excellent when identical cuts are made repeatedly.

- Workshops With Limited Space: Foot pedal machines are compact and easy to install.

- Budget-Conscious Buyers: More affordable than fully automatic or CNC models.

Foot Pedal vs. Fully Manual vs. CNC Shears

| Feature | Foot Pedal Shear | Manual Shear | CNC Shear |

|---|---|---|---|

| Speed | Moderate to High | Low | Very High |

| Cost | Medium | Low | High |

| Precision | High | Medium | Very High |

| Ease of Use | Easy | Moderate | Requires Training |

| Maintenance | Low | Low | High |

Conclusion: Foot Pedal Shears as a Productivity Tool

In industries where efficiency and accuracy are non-negotiable, foot pedal shearing machines strike a perfect balance between manual control and operational ease. They empower operators to work faster, safer, and with more precision—making them a smart investment for fabrication workshops and manufacturing units alike.

Are you ready to upgrade your shop’s efficiency with a reliable, operator-friendly shearing solution? As a manufacturer of pneumatic foot pedal shearing machines, we offer durable, precision-built models tailored to your needs.

👉 Contact us today to request a quote or schedule a demo.